What Are Rare Earth Elements and Why Are They So Important?

Rare earth elements (REEs) are a group of 17 metallic elements that include the 15 lanthanides on the periodic table, along with scandium and yttrium. Despite their name, these elements are not particularly rare in the Earth's crust, but they are rarely found in high concentrations, making their extraction difficult and costly.

Over the past few decades, rare earth elements have become essential to modern technology and global industry, powering everything from smartphones to renewable energy solutions. But why have these elements become so critical?

Learn more: What are Rare Earth Elements: The Top 10 Countries with the Largest Reserves

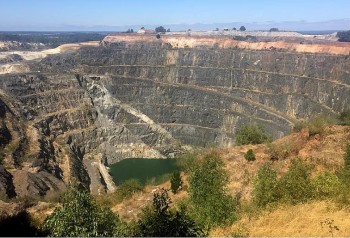

|

| A selection of some of the rare earth artificial rocks |

What Are Rare Earth Elements?

Rare earth elements are divided into two categories based on their atomic number and properties:

Light Rare Earth Elements (LREEs) – These include lanthanum, cerium, praseodymium, neodymium, and samarium. They are more abundant and commonly used in catalysts, glass polishing, and ceramics.

Heavy Rare Earth Elements (HREEs) – This group includes europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium, and yttrium. They are less common and are used in high-performance applications such as lasers, superconductors, and powerful magnets.

Why Have Rare Earth Elements Become So Important?

Rare earth elements have unique magnetic, luminescent, and electrochemical properties that make them indispensable for various high-tech and industrial applications. Here are some key reasons why they have become so valuable:

1. Essential for Modern Electronics

REEs play a crucial role in manufacturing smartphones, laptops, tablets, and other consumer electronics. Elements like neodymium and dysprosium are used in the tiny, powerful magnets that make miniaturized electronic components possible. Europium and terbium contribute to the vivid colors in LED screens and television displays.

2. Driving Renewable Energy Technologies

The push for clean energy has significantly increased the demand for rare earth elements. Wind turbines and electric vehicles (EVs) rely heavily on high-strength REE magnets to improve efficiency. Neodymium, praseodymium, and dysprosium are crucial components in permanent magnets that power wind turbine generators and EV motors, making these technologies lighter, more efficient, and longer-lasting.

3. Vital to National Security and Defense

REEs are critical for modern defense systems, including radar, communication systems, fighter jets, and missile guidance systems. The United States and other military powers depend on elements like yttrium for night-vision goggles, europium for laser targeting, and neodymium for stealth technology. Given their strategic importance, securing a stable supply of these materials is a priority for many governments.

4. Used in Healthcare and Medical Technologies

Medical imaging devices, including MRI scanners, utilize gadolinium as a contrast agent to enhance image clarity. Additionally, rare earth phosphors are used in X-ray machines and diagnostic imaging technologies. These elements have also found applications in cancer treatment, particularly in certain radiation therapies.

5. Enhancing Industrial and Aerospace Applications

The aerospace industry relies on rare earths for jet engines, high-temperature superconductors, and alloys used in satellites and spacecraft. These elements enhance the heat resistance and durability of materials used in extreme conditions, making them critical for space exploration and commercial aviation.

The Global Race for Rare Earth Elements

The supply of rare earth elements is not evenly distributed worldwide, leading to geopolitical tensions and economic competition. China dominates the global REE market, controlling around 60–70% of global rare earth production and refining. This dominance has led to concerns about supply chain vulnerabilities, especially for countries reliant on imports.

In response, the United States, Australia, Canada, and the European Union are investing heavily in alternative sources, including developing their own REE mining and refining facilities, promoting recycling programs, and seeking partnerships with countries like Vietnam and Brazil that have significant rare earth reserves.

Challenges in Rare Earth Element Production

Despite their importance, extracting and processing rare earth elements pose several challenges:

-

Environmental Concerns – REE mining generates significant environmental risks, including radioactive waste, water pollution, and habitat destruction. Sustainable mining practices and recycling efforts are being explored to mitigate these impacts.

-

High Costs and Technical Complexity – Separating rare earth elements from mined ore is a complex and costly process. The refining and purification processes require advanced technologies and expertise, which have been heavily concentrated in China.

-

Supply Chain Vulnerabilities – Geopolitical tensions and trade restrictions can disrupt the global supply of rare earths. Countries heavily reliant on imports are developing strategies to diversify their sources and reduce dependence on a single supplier.

The Future of Rare Earth Elements

As technology continues to advance, the demand for rare earth elements is expected to rise significantly. The transition to electric vehicles, expansion of renewable energy infrastructure, and increasing reliance on digital devices will further drive the need for these materials. Governments and industries worldwide are seeking innovative ways to secure a sustainable and stable supply of REEs.

Potential solutions include:

-

Developing New Mining Projects – Countries like the U.S., Canada, and Australia are investing in REE mining operations to establish alternative supply sources.

-

Recycling and Circular Economy Initiatives – Efforts to recover rare earth elements from electronic waste and old magnets are gaining traction as a more sustainable approach.

-

Substituting REEs with Alternative Materials – Researchers are exploring alternative materials and technologies to reduce dependence on rare earth elements in certain applications.

Conclusion

Rare earth elements are the backbone of modern technology, powering everything from smartphones to renewable energy solutions. Their unique properties make them essential for industries ranging from defense and healthcare to electronics and aerospace. However, their supply chain challenges and environmental impact pose significant hurdles that need to be addressed.

As the world moves towards greener and more advanced technologies, securing a stable and sustainable supply of rare earth elements will be crucial. Governments, industries, and researchers must work together to develop alternative sources, improve recycling efforts, and minimize environmental harm to ensure the long-term availability of these critical materials.

Rare earth elements may be hidden beneath the Earth's surface, but their impact on our daily lives is profound and undeniable. Understanding their importance is the first step in preparing for a future that depends on these powerful, yet often overlooked, elements.

Top 12 Largest Nickel Mines of the World by Production Top 12 Largest Nickel Mines of the World by Production Globally, there are currently over 186 nickel mines in operation. Discover now which 12 nickel mones are the largest in the world based on production. |

Top 10 Biggest Lithium Mines in the World by Production Top 10 Biggest Lithium Mines in the World by Production Currently, there are more than 26 lithium mines operating worldwide. Find out which lithium mines are currently producing the most today. |

Top 10 Biggest Coal Mines of the World By Reserve Top 10 Biggest Coal Mines of the World By Reserve Which is the world's largest coal mine? How much reserve does it have? View the list of the top ten largest coal mines worldwide. |

Top 10 Biggest Platinum Mines of the World by Production Top 10 Biggest Platinum Mines of the World by Production Currently, there are more than 68 platinum mines operating worldwide. Discover the top ten largest platinum mines in the world that are still in operation ... |

Top 16 Biggest Silver Mines of the World by Production Top 16 Biggest Silver Mines of the World by Production Currently, there are more than 743 active silver mines worldwide. Discover the top 15 silver mines in the world at the moment. |